Financement d'une durée inférieure ou égale à 3 mois consenti sous réserve d'acceptation par COFIDIS, SA à Directoire et Conseil de surveillance au capital de 67 500 000 €. Siège social Parc de la Haute Borne, 61 avenue Halley 59866 VILLENEUVE D'ASCQ Cedex - R.C.S LILLE METROPOLE SIREN N°325 307 106 enregistré auprès de l'ORIAS sous le numéro 07 02 34 93. Vous bénéficiez d'un délai légal de rétractation au titre de la vente à distance. Les frais s’élèvent à 0% du montant de la commande.

Financement d'une durée inférieure ou égale à 3 mois consenti sous réserve d'acceptation par COFIDIS, SA à Directoire et Conseil de surveillance au capital de 67 500 000 €. Siège social Parc de la Haute Borne, 61 avenue Halley 59866 VILLENEUVE D'ASCQ Cedex - R.C.S LILLE METROPOLE SIREN N°325 307 106 enregistré auprès de l'ORIAS sous le numéro 07 02 34 93. Vous bénéficiez d'un délai légal de rétractation au titre de la vente à distance. Les frais s’élèvent à 0% du montant de la commande.

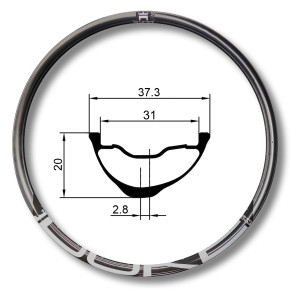

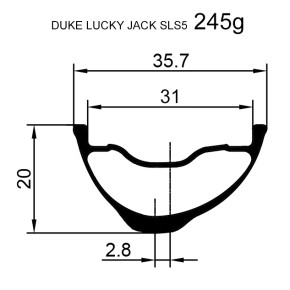

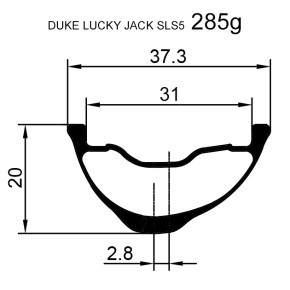

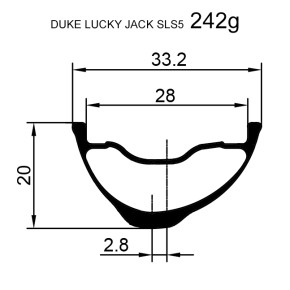

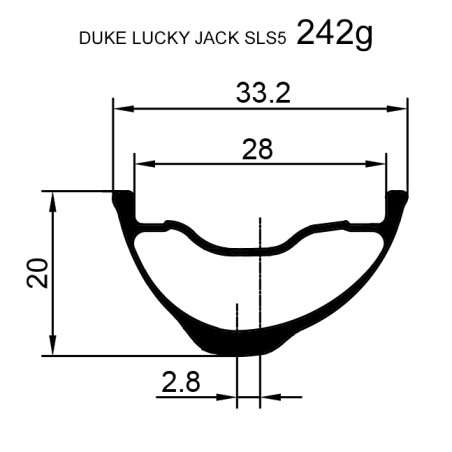

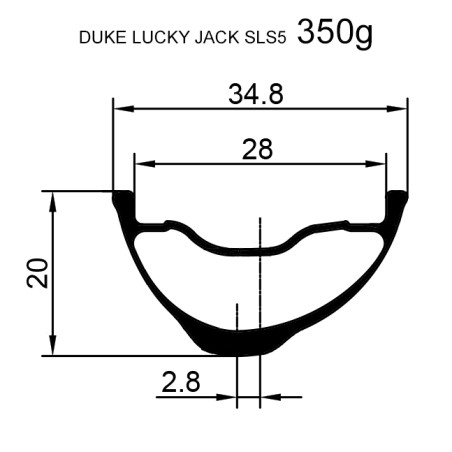

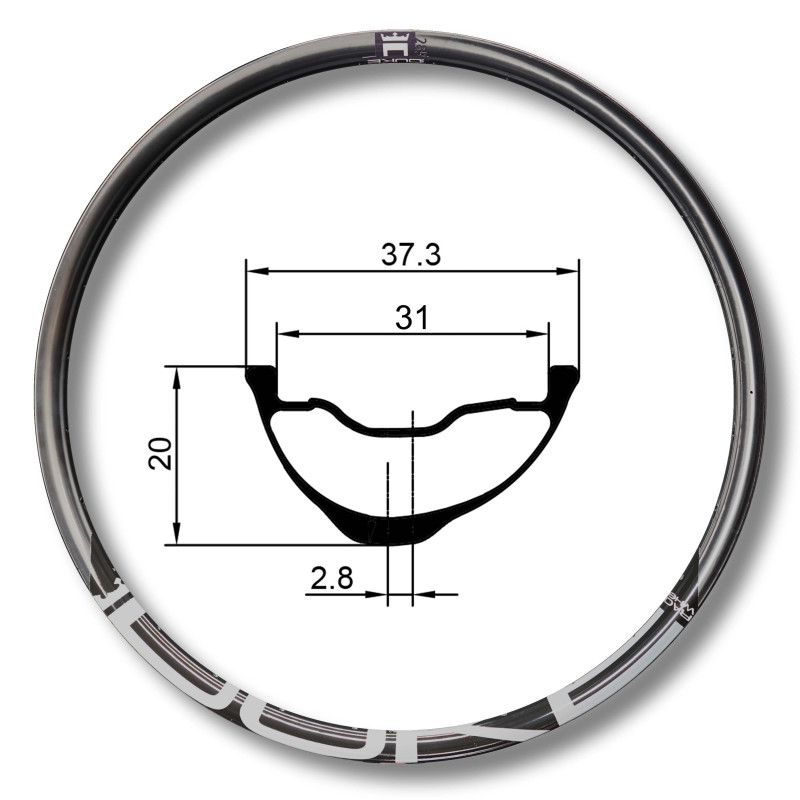

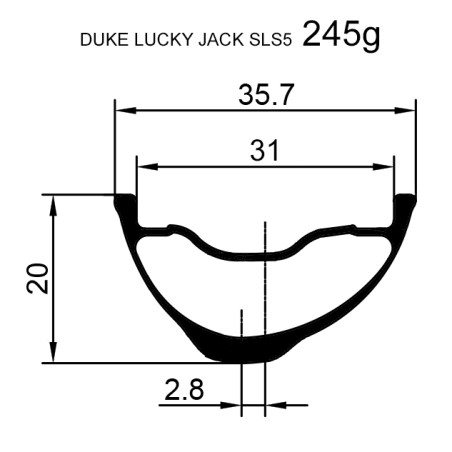

The new Lucky Jack SLS5 represents the pinnacle of high-end carbon XC wheels. Engineered to push the limits, it combines ultralight weight, responsiveness, and durability, while delivering unmatched ride comfort on the most demanding terrain. At 10% lighter, the Lucky Jack SLS5 also offers 15% more vertical compliance, resulting in improved dynamic performance. Available in two internal widths and three weight options, it’s the wheel of choice for top athletes on the XCO World Cup circuit, including Loana Lecomte, Kate Courtney, Jordan Sarrou, Titouan Carod, and David Valero.

Our recommended:

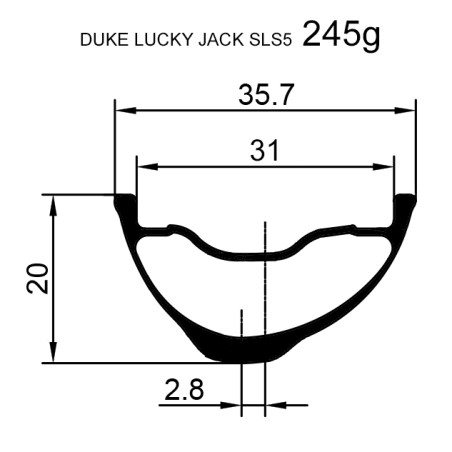

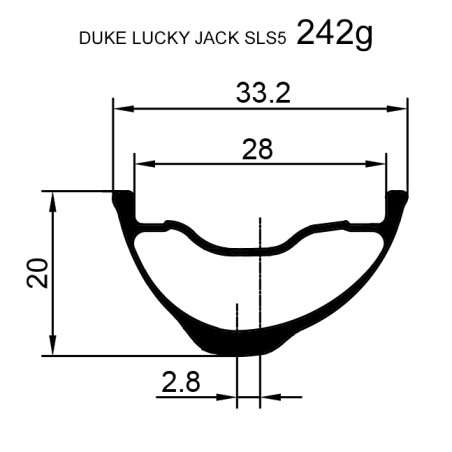

245 g: Front wheel for XC

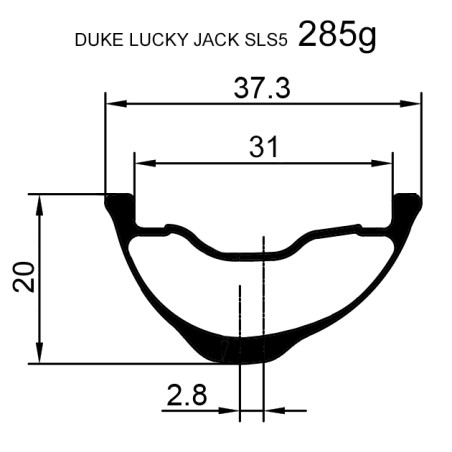

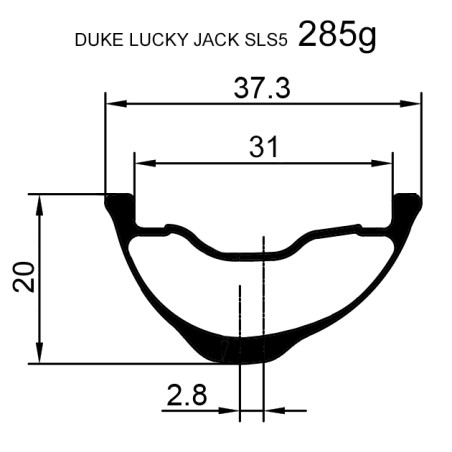

285 g: Rear wheel for XC or Front wheel for [very] aggressive XC

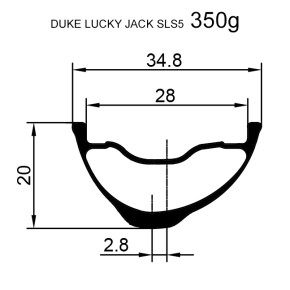

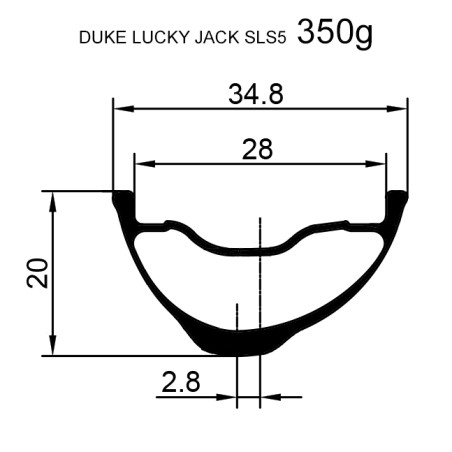

350 g: Rear wheel for [very] aggressive XC

Our SLS5 (Super Light Series 5) process combines optimized carbon fiber layups with an exclusive aerospace-grade resin.

10% lighter than its SLS4 equivalent.

15% more vertical compliance for better dynamic response. Increased resistance to lateral stresses and vertical impacts.

Enhanced vibration damping for greater comfort and control.

ImpactGuard – Energy-Absorbing Inserts High-resilience

inserts, pressure-injected into hollow cavities on either side of the rim, absorb both low and high-intensity impacts. They offer maximum protection without adding unnecessary weight – their density is comparable to our carbon fiber.

SpokeCore – Molded Spoke Holes

Thanks to an advanced manufacturing process, the spoke holes are directly molded into the rim structure. This eliminates the weaknesses and rigidity alterations often caused by drilling. The result : a one-piece construction that increases durability, allows for fewer spokes, maintains precise stiffness control, and ensures exceptional reliability.

By shaving weight off the new Lucky Jack, we’ve made the bike more agile through technical sections and more responsive to pace changes. But weight isn’t everything. Thanks to our DRC (Dynamic Response Comfort) technology, fully integrated into the SLS5 process, the new Lucky Jack delivers controlled deformation and optimized rebound management. What does that mean on the trail?

More responsiveness

Energy stored when entering a corner is unleashed for explosive acceleration out of it.

Better grip

Whether braking or accelerating, power transfer to the ground is optimized. You’ll feel more traction in corners and through technical terrain.

Increased comfort

Less fatigue in your upper body, even on long, demanding rides.

Greater control

Your bike feels calmer and more stable when the terrain gets rough.

Proven reliability

Unlike aluminum, carbon fiber doesn't fatigue under stress. By diffusing force across the rim, it reduces the risk of failure.

Technology

This technology has been successfully used on our MTB rims since 2011. It reduces rim weight. Strength is improved. The tire is slightly bigger. Carbon rims are simpler and more economical to manufacture.

Since 2021, our carbon rims benefit from a unique finish: incomparable brilliance and reflections thanks to a new process called VFP without varnish. This, also and above all, makes them more environmentally friendly by drastically reducing VOC and carbon dust emissions compared with a traditional rim. Without varnish, the rim is also harder on the surface, and more resistant to scratches.

6TERS is a concept of MTB rims differentiated between front and rear: a front wheel must maximize grip (inner width +), handling (rotational weight -) and control (lateral stiffness -). A rear wheel must provide traction, comfort (vertical stiffness-), stability (lateral stiffness +), efficiency (inside width -) and be stronger (reinforcements). Developed in collaboration with Julien Absalon (five-time world champion).

Thanks to this antiburp, the tire bead is held in position at all low pressures and under all loads, so there's no risk of the bead sliding off the rim or losing pressure even when cornering hard. Two edges prevent the tire beads from sliding horizontally towards the inside of the rim. Even after a puncture, the tire stays in place on the rim

Rim’s sidewalls are thickened to prevent cut of tires during impacts.

Our Tubeless compatible rims (UST, Tubeless Ready and Notubes), only require some Duke rim tape and a Tubeless-ready valve. They can also be used in a classic clincher set up (tyre & inner tube).

Rim offset increases lateral stiffness and wheel stability without adding weight. The rim holes are off-center, improving the spokes brace angles. By better balancing the tensions between the two spoke sides, the wheel's durability is enhanced.

Data sheet